Tower Semiconductor is planning three week-long shutdowns for most of its Newport Beach operations amid an industry slowdown — a move that will furlough nearly 700 workers.

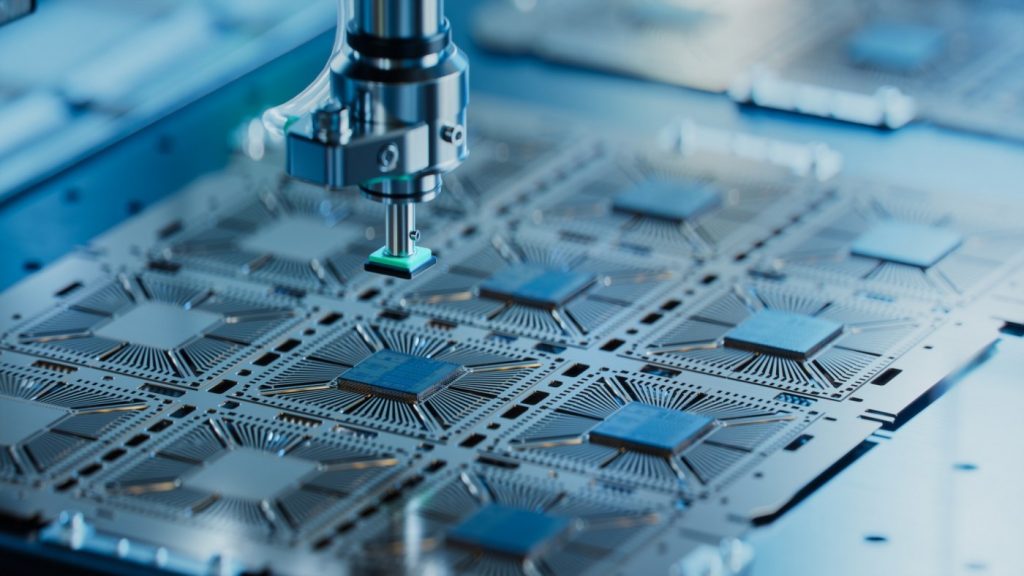

The Israeli-based chipmaker — which makes integrated circuits for the automotive, medical, industrial, aerospace and defense industries — confirmed it will shutter most of its operations April 1-7, with more partial shutdowns scheduled for July 1-7 and Oct. 7-13.

News of the shutdowns comes just seven months after Intel scrapped a $5.4 deal to acquire the chipmaker.

In a recent announcement to employees and the state Employment Development Department, Tower said its factory at 4321 Jamboree Road is seeing fewer orders as customers reduce inventory levels they built up over the past two years when semiconductor supplies were heavily constrained.

“We have been through challenging times in the past, and our team has always risen to meet those challenges,” Tower said. “We know that we will do that again in this instance. Experience teaches us that there are positive times ahead of us and we look forward to those times.”

Most of the company’s 699 employees will be asked to use accrued time off during the shutdowns, while others in safety, facilities management and customer support will work but be required to take an alternative week off by June 15th.

Employees who don’t have available time off can file for unemployment during those weeks, Tower said. The company didn’t reveal the total workforce count at its Newport Beach plant.

Tools will remain in a “warm idle state,” management said, and power will be shut off in areas of the plant that are not in use.

Tower said the week-long shutdowns are being scheduled to avoid to avoid a longer closure that could include job losses. Affected workers include engineering technicians, financial planners, manufacturing workers and utility operators.

Ironically, the company’s website lists 13 openings for a range of jobs, including a device engineer, an electrical engineer intern, an industrial engineer intern and a sales director for aerospace and defense, among other positions.

The 2020-2023 global chip shortage affected more than 169 industries and led to major price increases, long queues and reselling among consumers and manufacturers for automobiles, graphics cards, video game consoles, computers, household appliances and other consumer electronics that require integrated circuits.

Related Articles

Bay Area layoffs widen — but pace of tech job cuts in 2024 is below 2023

BottleRock Napa Valley to hold job fair for two festivals

California group, officials face return of old problem: child labor

“Restaurant row” kicks off in downtown San Jose with mini golf venue

California bus factory shuts, 425 jobs lost, latest victim of green-vehicle slump

The shortage was due to a perfect storm of factors, including supply chain backups and the COVID-19 pandemic. The health crisis fueled an increase in remote work and remote learning, causing a surge in demand for computers.

Other causes have been attributed to the China-United States trade war and the 2021 drought in Taiwan.

Intel last August scrapped its $5.4 billion deal to buy Tower Semiconductor after their merger agreement expired without regulatory approval from China, according to Reuters. Intel paid a termination fee of $353 million as a result.

That development underscores how tensions between the U.S. and China over trade, intellectual property and the future of Taiwan are spilling over into corporate dealmaking — particularly when it comes to tech companies.

Still, a February analysis from SeekingAlpha deemed Tower “very healthy liquidity-wise,” and on par with other semiconductor companies with good balance sheets.

Founded in 1993, Tower operates multiple manufacturing facilities in Israel, the U.S. (Newport Beach and San Antonio) and Japan through a partnership with Nuvoton Technology Corp.